Our biggest investment to date

Cedrus is at an inflection point, and after a lot of thought and hard work, we’ve decided to continue riding the momentum and further grow the business. Doing so however requires a major shift in our model and operations, and we are both excited and scared at the same time!

When I started Cedrus as a side hustle in 2017, I partnered with a technician who assembled the masts at his shop while I managed all design/engineering/orders/fulfillment/etc. Using contract manufacturing allowed me to work out of my house, and keep overhead extremely low. Basically my gross margin was very close to my net margin for the years that I outsourced production. It was also a very flexible business model; if I didn’t sell a mast, we didn’t make a mast. My partner had many other projects to keep him busy, and used Cedrus as filler work between larger jobs. With on-demand manufacturing, I never had to worry about my capital tied up in inventory, and could instead invest in new materials, processes, and technology. For a couple years, this model worked fairly well, and allowed me to finance and grow the business without any outside capital. I’m really proud of what I accomplished during this time, but the model is no longer working.

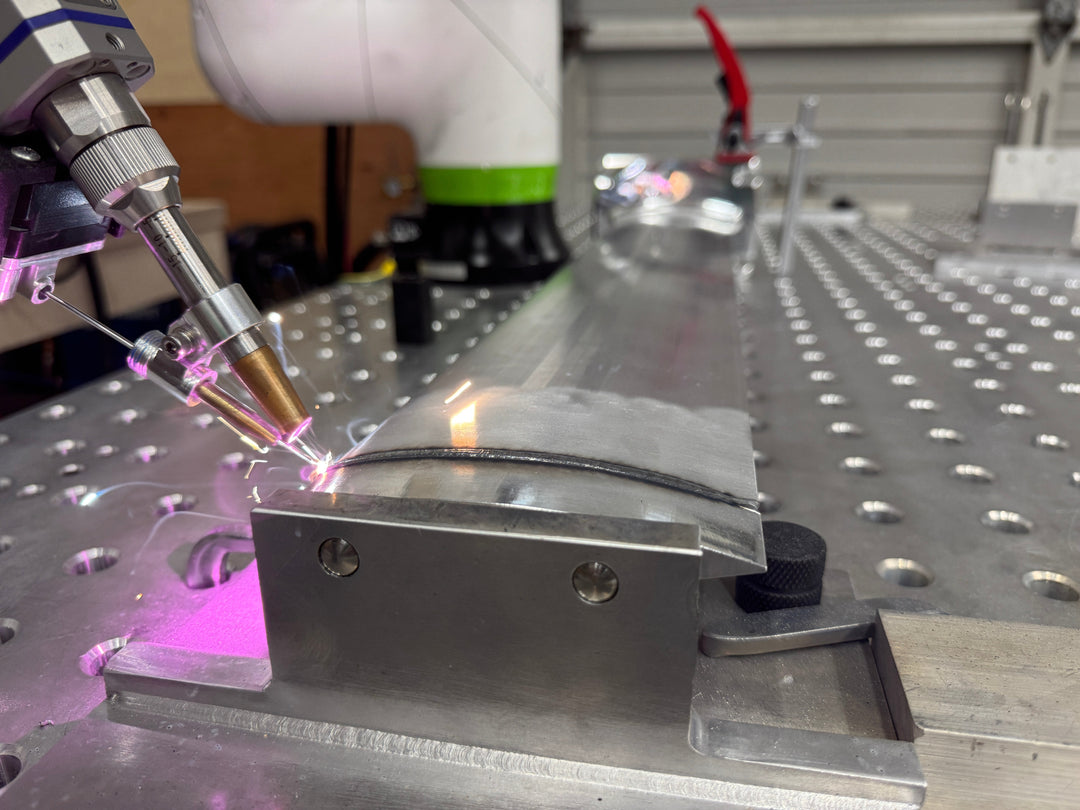

As demand for Cedrus masts grew, and with the launch of our Evolution lineup, our partner could no longer commit to production targets. Rather than spend energy trying to identify new contract manufacturing partners, we decided to instead invest in ourselves, finding the people and equipment we need to manufacture masts in-house, in the same facility that engineering and design takes place. This was a huge investment, again funded nearly entirely from revenue of mast sales. Paint booths, compressors, tooling, molds, and most importantly, floor space. In the last year, the economics of the business have changed dramatically as overhead begins to eat away at margins. Our old business model and gross margins look much more attractive, which is why pretty much every other foil brand outsources their manufacturing. Making stuff is really hard, and really expensive, but for me it’s the most rewarding part of the business. Without owning manufacturing, Cedrus would not be Cedrus.

But on-demand production in a sport/industry that is highly volatile and constantly changing has brought a lot of stress. There were many times we had to close orders due to an extended backlog of production and our inability to predict lead times in a post-covid, climate-crisis affected world. When we’d re-open, we’d have a flood of orders, quickly pushing delivery times beyond what we had just recently updated the site to. So we’d further extend the wait times, which would dramatically affect demand, creating an endless cycle of too much work (stress) and then too little work (also stressful). It quickly turned my dream of having my own small manufacturing business into a nightmare, as clients would email daily asking for updates or in some cases even cancel orders due to the delays. It was not sustainable.

In today’s world, we have learned that people want, and expect, their purchases now. We try communicate the hand-made, customized nature of the product, but not everyone is willing to wait. And as much as we wanted to think of ourselves as a custom bike frame builder, the reality is we are not. The only true variable is mast length (as opposed to the many unique dimensions of a bike frame). Don’t get me wrong, tracking 20 different lengths through production with individual serials is a lot of work. But at this point, we have a lot of data, and we have made the decision to begin producing popular length masts to carry inventory. Now people going on their dream foiling trip can buy a mast without the stress of wondering if it will be ready in time. Or with only a month or so left in your season, you can buy a Cedrus and make the most of it. Rest assured that if we don’t have your desired length in stock, we’ll be able to make what you want, and with a shorter lead time, thanks to inventory of other popular lengths.

To do this, we’re making the biggest investment we’ve ever made in the business, which is in the form of people. For many years, friends and family have told me casually to “just hire someone” to help reduce the stress and anxiety associated with manufacturing. Not so easy. First, finding people with the skills and passion for what we’re doing is really hard. Secondly, onboarding and training them pulls me away from making masts myself or addressing other business needs, which is a double negative. Not only do we have less income (not making masts) but our costs have doubled (2x the labor). This is the real reason Cedrus has stayed so small for so long. We simply haven’t had the bandwidth to hire. But we are so excited and grateful to introduce our new team members soon. With their help, I can now shift my focus to next generation products, manufacturing methods, materials, and processes. We strive for continuous improvement at Cedrus, but until now we’ve simply been in survival mode just hanging on for dear life as the foil rocket ship continues to accelerate.

Given the inventory and shorter lead times, we’re able to reduce the custom mast deposit to $100. We’re also excited to be trialing a new plan within Shopify that will make international purchases more transparent and hopefully cheaper. International sales make up a lot of our business, and we’re stoked to have Cedrus masts literally all over the world. But we understand that it can be unnerving waiting for UPS to deliver the mast along with a bill for duties and fees that you have no way to predict. The new plan will calculate duties and fees up front, allowing you to pay with your mast, so that there are no surprises on delivery day. We hope this works out, and appreciate any and all feedback from you as you go through the checkout process!

I want to thank those who’ve been patient waiting for masts, spreading the stoke of Cedrus, and helped us with feedback, and general positivity. This has been the hardest thing I’ve done in my life, and there have been more than a few times when I’ve re-considered my career. But now we’re doubling down on so many levels, from building inventory to our team, and even more motivated than ever to build the best foiling equipment in the world.

Thanks again, Kyle