Hardware & Foil Connections

Below is a summary of a blog post I published on September 23, 2022, after attending AWSI. The theme could not be more relevant today, so I am re-posting on the new site in a plea for brands and clients to recognize the risk of M6, M7, and SAE equivalent hardware in the use of hydrofoil connections. In summary, Cedrus does not design or specify the OEM foil connections and is not responsible for lost foils due to failure of these connections. Cedrus adapter and fuselage connections are arguably the stiffest and strongest in the industry, relying on a combination of M10 and M8 steel and titanium hardware. Foils that connect to the adapter using M6, M7, or SAE equivalent hardware are at higher risk of being lost than those which connect using properly sized hardware. If you have concerns about the strength of your foil connection, don't hesitate to contact us.

----

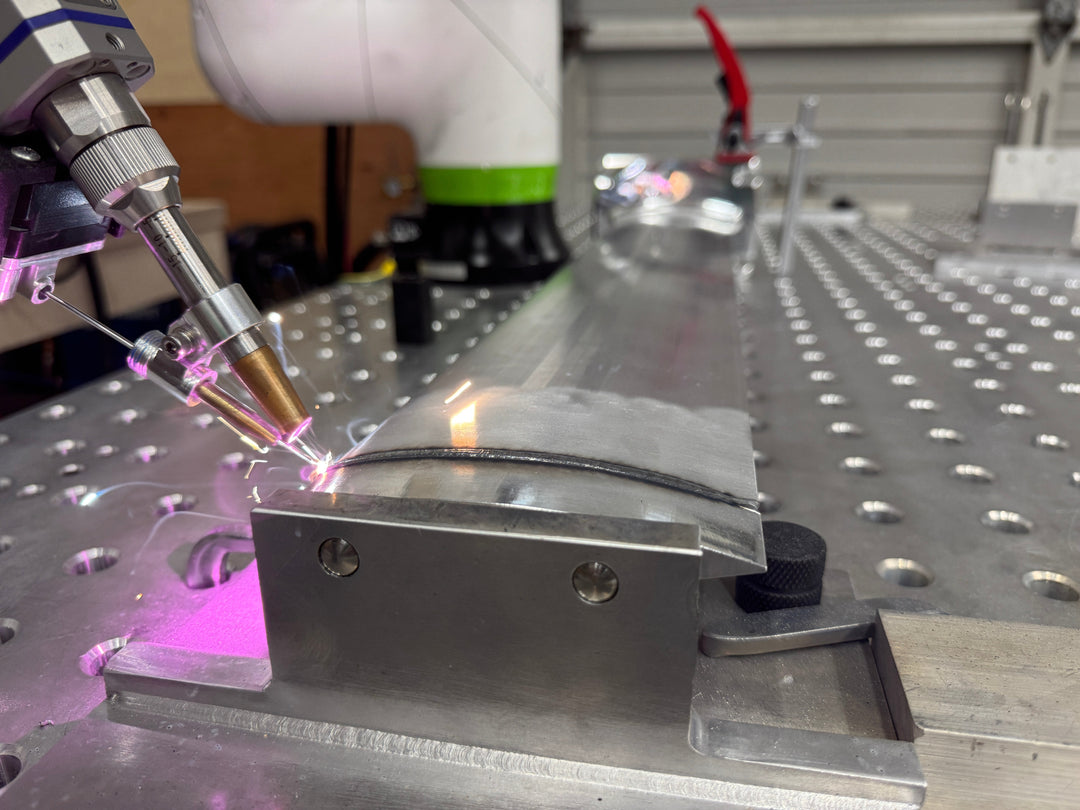

First off, at AWSI I was amazed to see how much the industry has changed since I delivered Launch Customer masts in 2018, which was also coincidentally my last visit to AWSI. Back then, it was all kite foiling, Kanaha Shapes pocket boards were the rage, and Moses 633 were the foil wings to have. I think I remember seeing prototype slingwings at the time, and most participants were teasing the nascent sport. Now, there are so many new foil brands, and I bet even the dock start crowd and market is bigger than kite. As a result, wings are massive, some over 1.3m (longer than my longest mast), and boards are getting monstrous too. It is important to note that board size has just as big of an impact on mast loads as wingspan, something foil designers I talked to at the show failed to acknowledge. Masts are getting stiffer, but they are also getting heavier and more expensive, due to higher modulus materials. Interestingly, brands appear to be trading thickness for chord length, which has an equally significant impact on drag… but that’s another post.

I want to take a moment to sympathize with the entire industry when I say that athletes are pushing this sport faster and further than we can design and manufacture, especially in a post-covid world. Warranties are typically in place to protect customers from equipment failures due to quality issues, however the types of failures I am seeing these days are simply due to usage loads exceeding design capability of the equipment. On one hand it’s not our fault that a customer breaks a mast from 2020 using a new set of foil foil wings and high volume board that didn’t exist when the mast was designed in 2017. On the other hand, brands should not introduce new wings and boards that are not capable of withstanding the forces of aggressive pumping, big boosts, or extreme wind conditions. It’s a difficult balance, because we want the sport to progress, but we also don’t want to go out of business. I beg all of my clients and those that are not my clients to understand that we are all trying our best to deliver equipment to you that allows you to progress and have fun. This sport is still so new, we are all learning, and limits are constantly being pushed. I am very proud to say that since 2018, with over hundreds of masts sold, I have not had a single structural failure of a mast. But some of these new wings scare me a bit, and at this rate, it is only a matter of time before someone exceeds the design capability of Project Cedrus. So before this happens, I want to discuss the importance of hardware and help mitigate some of the risk I am taking by making a universal foil mast.

M6 hardware (and SAE equivalent) is no longer adequate (arguably it never was) for mast/fuselage connections. As far as I know, there have been only 3 lost foils among Cedrus clients (<1% failure rate), and all 3 were a result of M6 hardware failures. The failure mode is the same: The aft screw fails in tension, and then the remaining screws do not have enough strength to manage the resulting bending loads. To reiterate: the aft screw is failing in tension, NOT SHEAR. An M6 has approximately 50% less strength in tension than an M8 screw. More importantly, an M8 has 2.4x more strength in bending than an M6 screw, which is usually how the forward screws fail once the aft has broken. Also, screws typically loosen before they break, and when they are loose, they are subject to bending stress. M8 hardware not only gives much higher initial strength, but the failure mode is more ductile which usually gives you the opportunity to stop foiling before your fuselage has sunk to the bottom of the lake/river/ocean.

Helicoils do not add strength to M6 connections, because it’s usually the hardware itself that’s critical. Helicoils do improve wear and corrosion resistance, but do not solve the fundamental problem of inadequate screw strength. As far as I know, Project Cedrus was the first foil to employ stainless helicoils, and I am well aware of their function, benefits, and limitations. I realize some brands have employed helicoils in their M6 connections, and I have started adding them to remaining M6 adapters, but the do very little to increase overall strength of the connection.

Use Cedrus M6 adapters at your own risk. We will not and cannot afford to compensate for your lost foil due to M6 hardware failures. I realize again that there is a risk to making a universal hydrofoil mast that I must accept. If you legitimately break an adapter, the mast itself, or the connection between the adapter and mast, I will obviously make it right. But we have experienced very angry clients who are adamant that lost foils are the result of defective Cedrus adapters, when the failure mode obviously matches similar pictures found on various forums and facebook groups of the same OEM connection. Most major foil brands have transitioned away from M6 hardware for obvious reasons (SAB, Takuma, Naish for example). While I appreciate brands maintaining their fuselage connections as long as possible as a form of goodwill to their customers, in the case of M6 I believe the risk exceeds the reward. I am not writing this to trash other brands or designs, I am simply offering engineering/technical advice based on data and my 8 years of studying every foil connection on the market in addition to my nearly 20 year engineering career specifying flight critical hardware. Feel free to ignore my technical advice, but please do not question my intentions or accuse me of trashing other brands. I see all brands as partners, not competitors, and simply want to help them sell more wings and give my clients more freedom and performance with Cedrus masts.

Not all M6 connections are created equal. Some have fared just fine over the years, and we have not heard of or seen failures. Connections that use a mortise and tenon/tapered fit style connection, if designed properly and manufactured to tight tolerances, can have reduced hardware loads. Fuselage connections relying on a butt joint will result in higher hardware loads, and be more susceptible to failure. Contact us if you would like recommendations for fuselage connections that would work well for larger riders, bigger boards, or more aggressive forms of foiling (jumping).

Replace your hardware frequently. Foil screws are subject to repeated stresses well below strength values, however this can still induce fatigue failures. Mowing the lawn kite foiling is very different from pumping for hours in the surf. All hardware, either M6 or M8, OEM or Cedrus, needs to be evaluated and replaced whenever the thread pitch appears to have changed, the shank bent, or it looks corroded. Hardware is so cheap, it is best practice to just replace frequently to reduce risk.

Read the Owner’s Info section to properly care for and assemble your foil. I know everyone would prefer to leave their setup assembled in their van or on their porch, but there are some tradeoffs to a universal foil mast. I don’t love pumping my tires, lubing my chain, or checking shock pressures when I go mountain biking, but the bike performs better when I do. Tension your adapter bolts before use, dis-assemble and rinse frequently, and let me know if you have any issues that are not resolved when following instructions.

Thanks for reading, Kyle