Mast Flex: Setting the Record Straight

I'm going to start this post a bit more obnoxiously than usual: I am tired of hearing about mast flex. I started Cedrus 8 years ago after trying to convince brands and riders that the mast is really important, and that a stiff mast will result in better performing foils. No one believed me, and some brands actually said they "engineer their flex profile." I am not kidding. These same brands now sell high modulus masts. But honestly that's not what frustrates me. I'm actually pretty proud of the impact that Cedrus has had on this industry, and the first to admit that we are all still learning foil design. What's become so challenging for me to manage is the expectation that a mast shouldn't "flex." Also, modulus is an intrinsic mechanical property and does not mean "Ultra Stiff Mast," but refers only to the properties of material used. If you have even the most basic understanding of structural mechanics and materials science, you will understand that all structures will deflect when subject to loads, the amount which is dependent on material and design, even more by the latter. I can easily design an aluminum mast that's stiffer than a UHM carbon through design, even though aluminum is not as stiff as carbon (or steel, or titanium). Buildings sway in the wind. Bridges move when trucks transit. Airplane wings flutter through turbulence. Car bodies twist going around race tracks. I've spent 20 years designing and engineering all of those things. Sporting goods like skis, bikes, and golf clubs all experience "flex" or deflection under normal use conditions. It is simply impossible to design a structure that is so stiff that it literally does not move when subject to external loads. Probably the stiffest engineered structures out there are not even on this planet, but instead orbiting it and required to maintain a very accurate shape in order to reflect radio waves. But these structures are very fragile, and aside from surviving launch loads, would not be trusted to withstand any significant loads, perhaps even the weight of a human standing on it.

Back to the mast. It's gotten a little out of control. I watched people walk around AWSI bending and twisting masts sitting on the beach and scoffing as if experts in foil design. I've seen posts on forums that are beyond technically flawed and can't even comment anymore. We've stopped talking about how masts actually ride, and instead talk about dimensions like chord length and thickness. I'm not suggesting we go back to "engineering flex," but I'm begging that we not forget what's important here: what do you really need, and how does it feel when you ride it? This is obviously very hard to quantify objectively. Generally speaking, bigger riders and bigger foils will require stiffer masts. One could actually argue that a beginner foiler could benefit more from stiffness than an advanced rider, because the beginner hasn't really figured out control theory yet. But once you reach a point, why make the mast any stiffer, and sacrifice drag, weight, and cost in the process? The industry has become so fixated on stiffness, that we're starting to ignore other important variables like wetted area, price, weight, and strength. At Cedrus, we're not going to ignore those other variables. We have designed a fleet of high performance masts with varying levels of stiffness and price points, all without sacrificing strength, compatibility, or drag. Cedrus used to be seen as the slow kid on the block, but now we offer some of the lowest drag masts on the market. Forgive us for not necessarily being the stiffest as well. If it has not been made clear, foil/mast design is a constant balance and tradeoff between stiffness, strength, weight, cost, drag, compatibility, and manufacturability. We're balancing a lot here, and it's not easy.

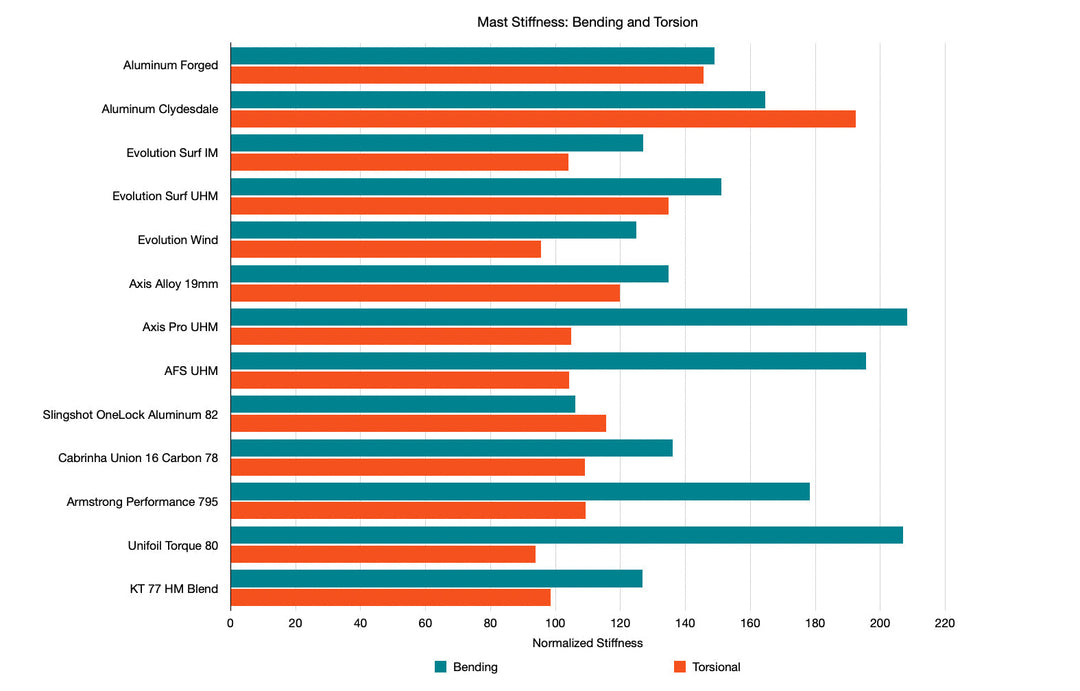

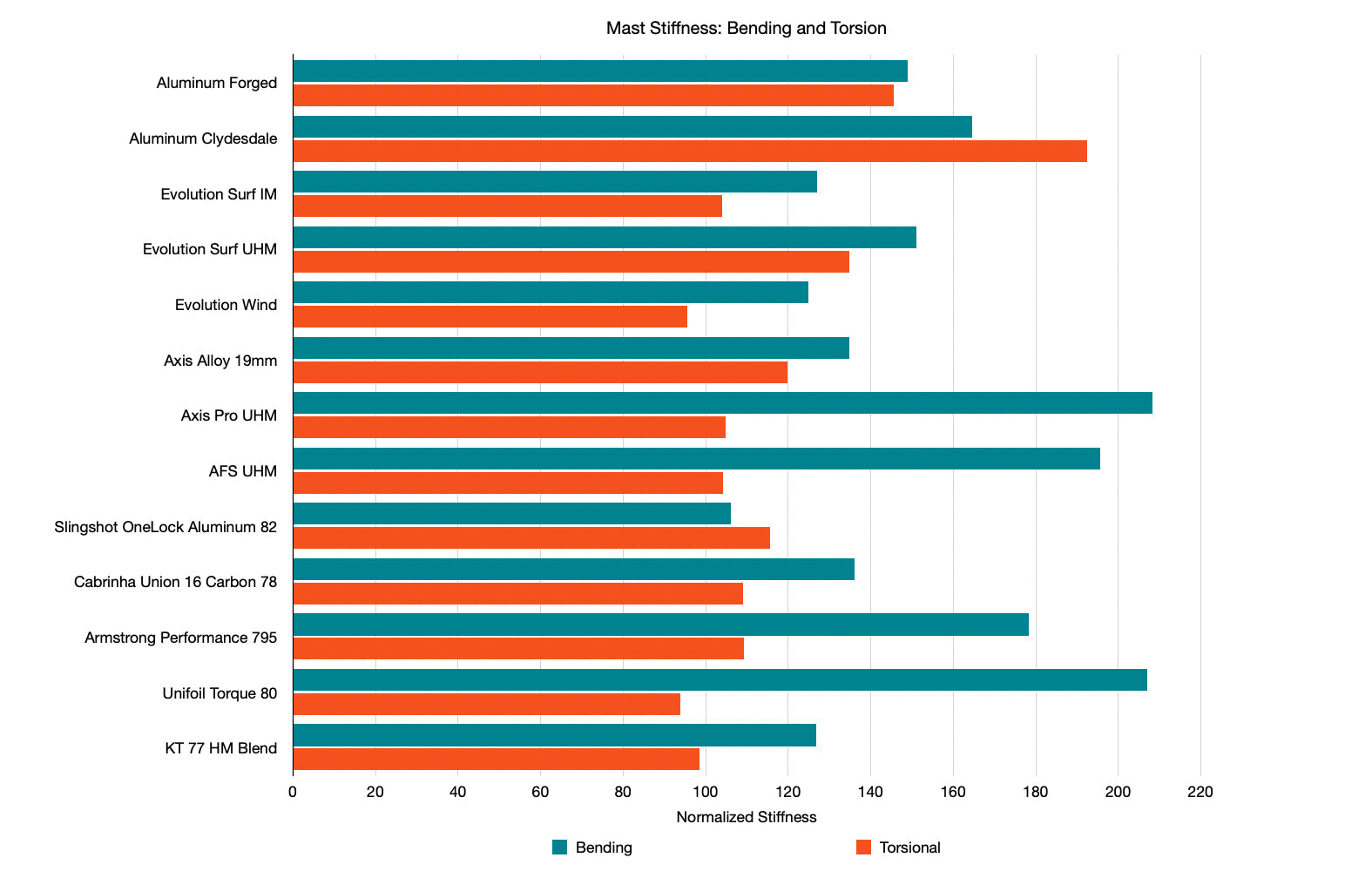

We're getting a lot of questions about our new aluminum masts, specifically related to stiffness. How can an aluminum mast be stiffer than high modulus carbon? That is another blog entry. But for those who've asked us to prove it, here's the data. We've tested a number of masts under two different loadcases: bending and torsion. We're not trying to hide or shame here, we're just trying to be transparent with data that riders have asked for. It's been really interesting, and as you can see Cedrus is not the stiffest. Our hope is to educate and compare, and to help you feel more comfortable investing in Cedrus. Obviously one cannot demo every single mast on the market, so we felt that objectively quantifying stiffness properties could help some riders with their decision, whether it means riding our mast or not.

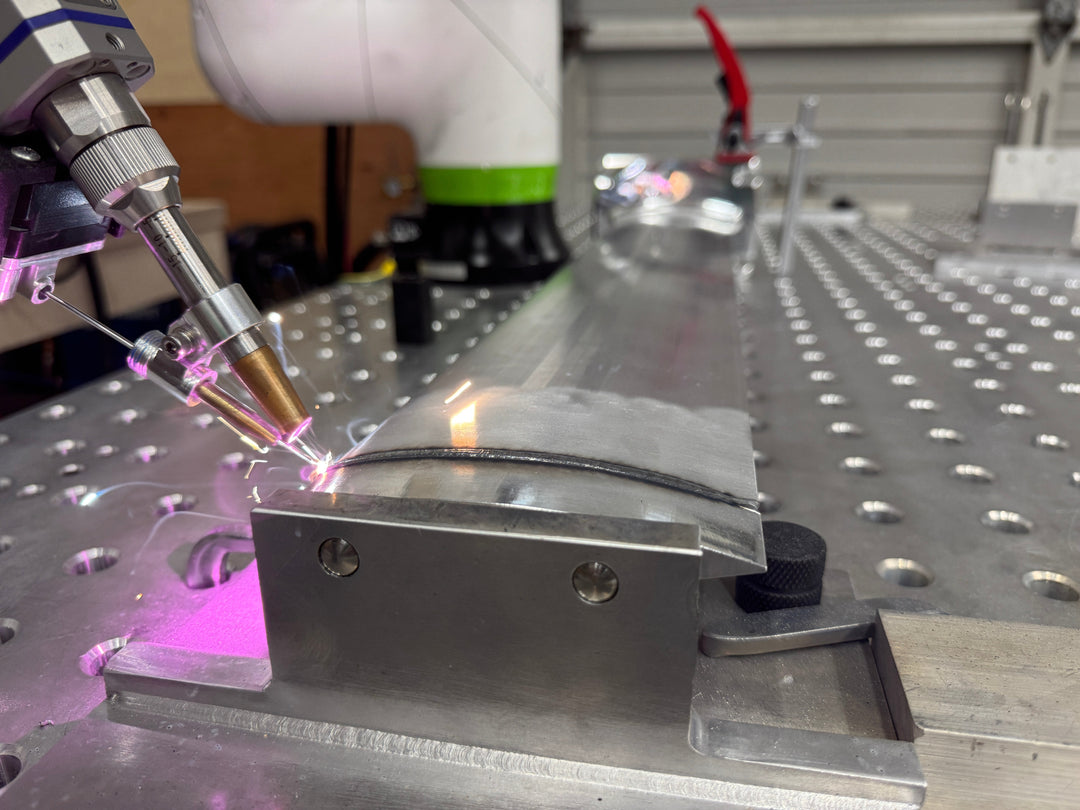

To test bending, the mast is loaded in an Instron Tensile Testing Machine that has been modified to apply compression force eccentrically to the mast. These machines are expensive, $50k+, but we were fortunate to find one on Craigslist years ago after a medical device company moved. Our custom test fixture results in a combined axial force and bending moment, which is similar to the loads the mast would be subject to when the rider turns by pushing on the rail of their board. Here's a shot of Chris ripping Evolution Surf, clearly mimicking the loadcase we are applying in the Instron. There's also a bit of torsion in here, and we'll get to that.

Forces and deflections are precisely recorded by the Instron. We can put enough load on the mast to break some models, but not Cedrus. The slope of the curve tells us how stiff the mast is. Any non-linearities suggest damage or failure, which you can see in the screenshot below. Yes, this machine requires Windows XP...

Torsion is applied through yaw. If you're not familiar with the difference between rolling and yawing, please google it. We characterize torsional stiffness using a more crude but still accurate method. The mast is bolted to a strongback (stiff, strong chunk of metal) and then supported with a pin at the fuselage end. When the tail is loaded, the mast twists about its axis, but does not bend. With a 60lb kettlebell, the tail end of the fuselage will deflect over an inch. Using trigonometry and a set of calipers, we can measure the torsional rigidity of the mast and normalize for length. As we all have experienced, shorter masts feel stiffer than longer masts, but we compensate for that. Longer fuselages put more load on the mast than shorter fuselages, and again we have accounted for all of this.

I didn't used to believe that torsional stiffness was particularly important. As an intermediate kite foiler when designing Cedrus in 2017, my gybes were still relatively slow, and I thought bending stiffness was key to stability and control. But I have since converted to believing that torsional stiffness is just as important, if not more, to more advanced riders. Prone foilers who slash waves and DW riders absolutely love masts with high torsional stiffness. When coupled with a short chord length, these masts can turn on a dime, offering super snappy turns and a more playful feel in the surf or swell. I have also learned through extensive riding that rolling turns induce a torsional force or twisting action on the mast due to the coupling nature and interaction of roll/yaw moments. Our new surf mast feels markedly stiffer than the launch generation, but features the same bending stiffness. Is there an optimal relationship between bending and torsional stiffness characteristics of a mast? Probably. But I will be the first to admit that I don't know that relationship yet, and it likely depends on the rider and the foils. But we are certainly doing our best to consider both in our design process, and to build a well balanced mast. This is evidenced below, where you see a healthy blend of bending and torsional stiffness properties among Cedrus masts.

Here's the data so far. Again, this is normalized for mast length using the equations below. It's quite interesting. One trend immediately obvious to me is the UHM masts (AFS, Axis Pro, Unifoil Torque) are clearly optimized for bending stiffness. Surprisingly, they lack even the torsional stiffness of the 19mm alloy mast. On second thought, this is not entirely surprising, because the 0 degree fibers that contribute most to bending stiffness have much lower shear stiffness than those running at 45 degrees. You can see that aluminum masts (Axis 19m, Cedrus, and One-Lock) have much more balanced stiffness characteristics due to the isotropic nature of the material. I'm not making any claims as to which is better than the other, or faulting any of these masts... I am simply presenting the data. If stiffness is super critical to you, and you're looking at Cedrus, I'd suggest you go with aluminum or Surf UHM. If you're an average size human riding small-mid size performance foils, Evolution Surf and Wind will perform super well for you and give you better speed and drag characteristics. It's a constant tradeoff, and we're trying to be honest about that. We do not have a single marketing employee at our company. Our goal is to update our site to make it easier to determine which model is right for you, even if it's not a Cedrus.

In closing, I just want to reiterate that we not forget why we foil: to have fun, stay healthy, socialize with our friends, and learn new things. The mast stiffness competition is getting out of control, and our intent with this data is not to fuel the fire, but to present empirically derived data and put an end to "beach flex tests" or baseless forum banter. Have a mast you'd like tested? Send it in and we'll test it! Or better yet, just go ride your foils and be stoked:) We're happy to share the data, and the results will be helpful to designers and riders alike.

Happy foiling, Kyle